- Home

- About us

- Mineral Processing EPC

- Products

-

- Crushing

- Screening

- Grinding

- Classifying

- Agitation Equipment

- Flotation

- Gravity Separation Equipment

- Magnetic Equipment

- Thickening

- Dewatering Machine

- Gold Extraction Equipment

- Feeding

- Transmission Equipment

- Iron Removal Equipment

- Automatic Control Equipment

- Wear – Resistant Rubber Products

- Valves

- Hydrocyclone

- Pumps

-

- Solutions

-

- Gold CIP Production Line

- Gold CIL Processing Line

- Gold Flotation Production Line

- Cu-Pb-Zn Dressing Process

- Gold Heap Leaching Process

- Molybdenum Dressing Production Line

- Quartz Sand Dressing Production Line

- Hematite Separation Process

- Phosphorite Flotation Equipment Production Line

- Manganese Ore Magnetic Separation Production Line

- Magnetite Separation Production Line

- Scheelite Flotation Production Line

- Fluorite Flotation Process

- Silver Flotation Process

- Barite Mineral Processing

- Antimony Mineral Processing

- Wolframite Mineral Processing

- Chrome Ore Mining Process

- Iron Ore Mining Process

- Tin Ore Mining Process

- Nickel Ore Mining Process

- Graphite Ore Beneficiation Process

- Tailings Re-Processing Line

- Titanium Mining Process

- Dolomite Mining Process

- Kaolin Mining Process

- Pyrite Mineral Process

- Zircon Ore Mining Process

- Magnesite Flotation Process

- More >>>

-

- Cases

- News

- Contact Us

Rod Mill

- Product Introduction

- A grinding equipment with steel rod as medium

- Capacity

- 0.62~250t/h

- Product Improvement

- Xinhai rod mills include overflow rod mill, end peripheral discharge rod mill and center peripheral discharge rod mill, which could meet different requirement.

Advantages

The steel rod takes regular movement in mill

It is convenient to install and maintain

Rapidly discharging

Even particle size of product, little over grinding

Product Introduction

The name of rod mill is from the medium in mill is steel rod. The rod mill is generally wet overflow type used in the first stage grinding, especially in artificial sand and stone, mineral processing plant and power sector of chemical plant.

Product Principle

The rod mill is driven by motor with speed reducer and peripheral large gear, or low speed synchronous motor with peripheral large gear. The grinding medium --- steel rod is put into the cylinder which is lifted, and then fall under the action of the centrifugal force and friction force. The materials entering into cylinder form the feeding inlet are grinded by movable grinding medium and discharged out by overflow and continuously feeding.

Grinding medium

The grinding medium of rod mill is steel rod which is recognized that the length of rod is less than 7m because the large length is easy to twine. The diameter of rod is 75~150mm

Grinding rod should have enough stiffness and hardness to keep straight, and it should not be too crisp which causes the rod broke into pieces without enough wear. If the rod is too soft, it is easy to bend and twine which makes trouble to clean machine

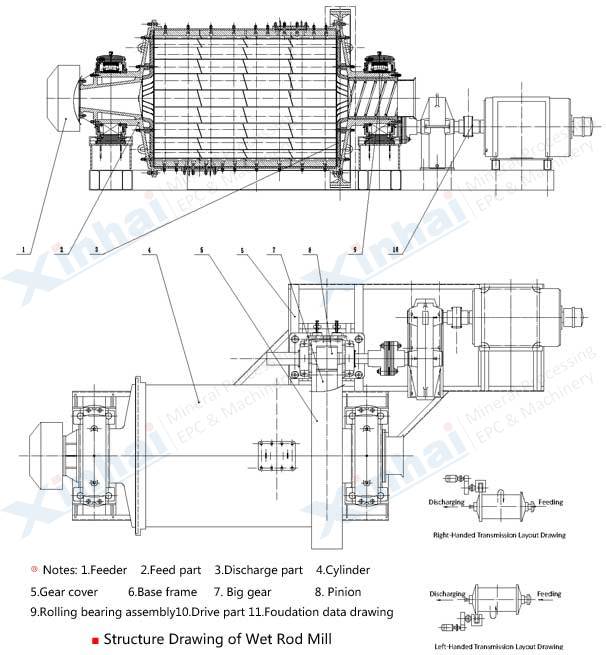

Product Structure

(1)Rod mill is usually selected in order to prevent over grinding in gravity or magnetic separation plant of tungsten tin and other rare metals mine

(2)In two stages grinding, the capacity of rod mill used in the first stage grinding is larger than ball mill’s

(3)In some cases, rod mill can replace short head cone crusher

Technical Parameters

| Model | Cylinder Diameter (mm) |

Cylinder Length (mm) |

Motor Model | Motor Power (kW) |

Motor Revolution (r/min) |

Length (mm) |

Width (mm) |

Height (mm) |

Capacity (t/h) |

Effective Volume (m3) |

Weight (kg) |

| MBY0918 | 900 | 1800 | Y225M-8 | 22 | 730 | 4980 | 2370 | 2020 | 0.62~3.2 | 0.9 | 5700 |

| MBYg0924 | 900 | 2400 | Y225M-8 | 22 | 730 | 5001 | 1865 | 1400 | 0.81~4.3 | 1.2 | 6443 |

| MBY1224 | 1200 | 2400 | Y280M-8 | 45 | 730 | 6450 | 2800 | 2500 | 0.4 ~4.9 | 2.28 | 12308 |

| MBY1530 | 1500 | 3000 | JR125-8 | 95 | 725 | 7935 | 3185 | 2280 | 5 | 19990 | |

| MBYg1530 | 1500 | 3000 | JR117-8 | 80 | 725 | 7253 | 3070 | 2280 | 2.4 ~7.5 | 5 | 21210 |

| MBYg2130 | 2100 | 3000 | JR136-8 | 180 | 735 | 8122 | 4220 | 3073 | 14 ~35 | 9 | 42123.5 |

| MBYg2136 | 2100 | 3600 | JR137-8 | 210 | 735 | 8958 | 4320 | 3025 | 43 ~61 | 10.8 | 45800.5 |

| MBYg2430 | 2400 | 3000 | JR138-8 | 280 | 735 | 9004.5 | 4836.4 | 3490 | 11.5 | 55795 | |

| MBYg2732 | 2700 | 3200 | JR157-8 | 320 | 750 | 10509 | 5000 | 3620 | 15.7 | 83110 | |

| MBYg2736 | 2700 | 3600 | JR1510-8 | 380 | 743 | 10764 | 5150 | 3620 | 32 ~86 | 17.7 | 90441 |

| MBY2740 | 2700 | 4000 | TDMK400-32 | 400 | 187.5 | 12300 | 5700 | 4700 | 43~110 | 20.4 | 75000 |

| MBY3040 | 3000 | 4000 | JR1510-8 | 570 | 740 | 9800 | 3900 | 3900 | 54~135 | 26 | 90000 |

| MBY3245 | 3200 | 4500 | TDMK800-36 | 800 | 167 | 14600 | 7000 | 5300 | 64~180 | 31 | 113000 |

| MBY3645 | 3600 | 4500 | TDMK1250-40 | 1250 | 150 | 15200 | 8800 | 6800 | 80~230 | 41.8 | 139000 |

| MBY3654 | 3600 | 5400 | TDMK1600-40 | 1600 | 150 | 15900 | 8800 | 6800 | 100~250 | 49.7 | 150000 |

Related Articles

Guestbook

Please leave your message here! We will send detail technical info and quotation to you!

Related Products

Raymond Mill | Cylinder Energy-Saving Overflow Ball Mill | Autogenous Mill |

Mineral Processing

EPC and Equipment

Tel: 0086 13025991453

E-mail: marketing@ytxinhai.com

Home

About us

EPC

Products

Solutions

Cases

News

Contact Us

3D Exhibition Room

sitemap

© 2014 Shandong Xinhai Mining Technology & Equipment Inc.