- Home

- About us

- Mineral Processing EPC

- Products

-

- Crushing

- Screening

- Grinding

- Classifying

- Agitation Equipment

- Flotation

- Gravity Separation Equipment

- Magnetic Equipment

- Thickening

- Dewatering Machine

- Gold Extraction Equipment

- Feeding

- Transmission Equipment

- Iron Removal Equipment

- Automatic Control Equipment

- Wear – Resistant Rubber Products

- Valves

- Hydrocyclone

- Pumps

-

- Solutions

-

- Gold CIP Production Line

- Gold CIL Processing Line

- Gold Flotation Production Line

- Cu-Pb-Zn Dressing Process

- Gold Heap Leaching Process

- Molybdenum Dressing Production Line

- Quartz Sand Dressing Production Line

- Hematite Separation Process

- Phosphorite Flotation Equipment Production Line

- Manganese Ore Magnetic Separation Production Line

- Magnetite Separation Production Line

- Scheelite Flotation Production Line

- Fluorite Flotation Process

- Silver Flotation Process

- Barite Mineral Processing

- Antimony Mineral Processing

- Wolframite Mineral Processing

- Chrome Ore Mining Process

- Iron Ore Mining Process

- Tin Ore Mining Process

- Nickel Ore Mining Process

- Graphite Ore Beneficiation Process

- Tailings Re-Processing Line

- Titanium Mining Process

- Dolomite Mining Process

- Kaolin Mining Process

- Pyrite Mineral Process

- Zircon Ore Mining Process

- Magnesite Flotation Process

- More >>>

-

- Cases

- News

- Contact Us

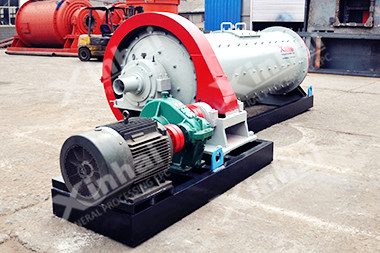

Energy Saving Ball Mill

- Product Introduction

- A high efficiency and energy saving ball mill with rolling bearing

- Capacity

- Up to 160t/h

- Product Improvement

- Cylindrical energy saving grid ball mill is lined grooved ring plate which increases the contact surface of ball and ore and strengthens the grinding.

Advantages

Large double row self-aligning roller bearing with low friction force is used to replace sliding bearing, which is easy to start and saves 20-30% energy.

Cylindrical energy saving grid ball mill is lined grooved ring plate which increases the contact surface of ball and ore and strengthens the grinding.

Large ore outlet and large capacity

The mill with diameter below 2.1 meters adopts whole machine frame, which is convenient for civil construction and equipment installation.

Oil mist lubrication device guarantees the lubrication of all gears

Product Description

Cylindrical energy saving grid ball mill is one of energy saving mills developed by Xinhai, which is easy to start and saves 20-30% energy. It is lined grooved ring plate which increases the contact surface of ball and ore and strengthens the grinding. In addition, the large ore outlet increases the capacity. The particle size of grinding product is coarse, so it is applied in first grinding.

Work Principle

The main part of cylindrical energy saving grid ball mill is cylinder with small diameter and large length rotating slowly by the transmission device. The material is fed from the cylinder inlet and grinded by the impact of steel ball and ore and self-grinding. Due to the continuously feeding material, the pressure pushes material to the outlet and the grinded material is discharged from the cylinder outlet. In wet grinding, material is taken out; in dry grinding, the material is taken out by air. The grid installed in the outlet of mill is relied for forced discharge. Low pulp surface in cylinder reduces the ore over-grinding, and prevent the steel ball out. Under the same production conditions, production capacity of grid mill is larger than overflow mill’s. Both ends of the cylinder body adopt rolling bearing instead of the sliding bearing, which is more energy-saving.

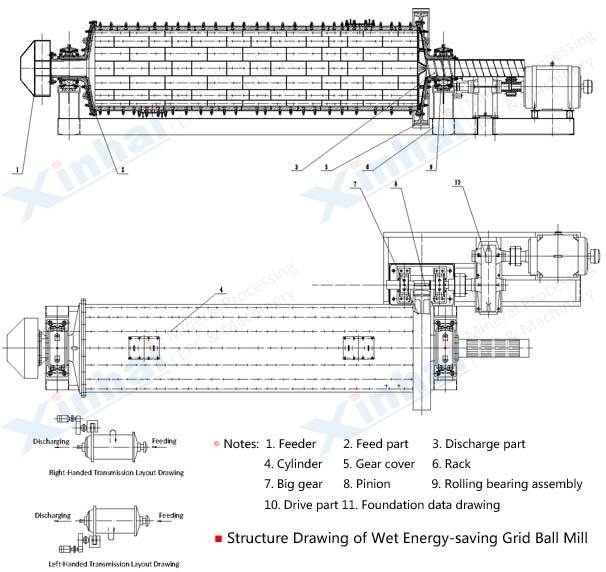

Product Structure

Cylindrical energy saving grid ball mill consist of feeding part, discharging part, rotary part, transmission part (reducer, small gear, motors, electrical control) and other major parts. Hollow shaft is steel castings, and the liner is detachable. Rotary gear is processed by casting hobbing. The cylinder is lined wear-resistant liner plate with good resistance to wear. This machine works stably.

Product Separation

The mill with coarse particle product is common used in the first stage grinding

Technical Parameters

| Model | Cylinder Diameter (mm) |

Cylinder Length (mm) |

Motor Model | Motor Power (kW) |

Length (mm) |

Width (mm) |

Height (mm) |

Capacity (t/h) |

Effective Volume (m3) |

Max. Ball Load (t) | Weight (kg) |

| MQGg 1212 | 1200 | 1200 | Y200L2-6 | 22 | 3512 | 2076 | 1620 | 0.17 ~4.1 | 1.14 | 2.4 | 9610 |

| MQGg 1224 | 1200 | 2400 | Y280M-8 | 45 | 5745 | 2352 | 1778 | 0.26~6.15 | 2.4 | 4.6 | 12692 |

| MQGg 1240 | 1200 | 4000 | JR117-8 | 80 | 7990 | 2210 | 2262 | 0.34~8.3 | 3.8 | 7.8 | 15932 |

| MQGg 1515 | 1500 | 1500 | Y280M-8 | 45 | 5740 | 3075 | 2280 | 1.4 ~4.5 | 2.2 | 5 | 17125 |

| MQGg 1530 | 1500 | 3000 | JR117-8 | 80 | 7253 | 3070 | 2280 | 2.8 ~9 | 5 | 10 | 21425 |

| MQGg 1536 | 1500 | 3600 | JR126-8 | 110 | 8595 | 3185 | 2280 | 3~11 | 5.4 | 11.4 | 24213 |

| MQGg 1545 | 1500 | 4500 | JR127-8 | 130 | 9680 | 3254 | 2370 | 3.5~12.5 | 7 | 12 | 27346 |

| MQGg 1830 | 1800 | 3000 | JR136-8 | 180 | 8250 | 3620 | 2785 | 4.5 ~27 | 6.65 | 14 | 31850 |

| MQGg 1836 | 1800 | 3600 | JR136-8 | 180 | 8866 | 3683 | 2785 | 4.5 ~29 | 8.2 | 13.8 | 35467 |

| MQGg 1845 | 1800 | 4520 | JR137-8 | 210 | 9808 | 3683 | 2785 | 5~35 | 10.2 | 19 | 38909 |

| MQGg 1856 | 1800 | 5620 | JR137-8 | 210 | 10909 | 3683 | 2785 | 6~40 | 12.2 | 22 | 41681 |

| MQGg 1870 | 1800 | 7020 | JR138-8 | 245 | 12404 | 3783 | 2735 | 7~50 | 15 | 31.5 | 45166 |

| MQGg 2122 | 2100 | 2200 | JR128-8 | 155 | 7135 | 4137.7 | 3083 | 5~29 | 6.6 | 20 | 38340 |

| MQGg 2130 | 2100 | 3000 | JR136-8 | 180 | 8220 | 4220 | 3083 | 6.5 ~36 | 9 | 27 | 43100 |

| MQGg 2136 | 2100 | 3600 | JR137-8 | 210 | 9154.5 | 4320 | 3433 | 7.5 ~42 | 10.8 | 23.5 | 45833 |

| MQGg 2140 | 2100 | 4000 | JR137-8 | 210 | 9654 | 4320 | 3083 | 7.5 ~45 | 12.8 | 22.5 | 47262.4 |

| MQGg 2145 | 2100 | 4500 | JR137-6 | 280 | 10350 | 4253 | 3125 | 10 ~50 | 13.5 | 23.6 | 52648 |

| MQGg 2230 | 2200 | 3000 | JR137-8 | 210 | 8220 | 3864 | 3183 | 7.5 ~45 | 9.8 | 20.6 | 44600 |

| MQGg 2430 | 2400 | 3000 | JR138-8 | 280 | 9023.5 | 4836.4 | 3490 | 7.2 ~92 | 11.5 | 22.5 | 59544.5 |

| MQGg 2436 | 2400 | 3600 | JR138-8 | 320 | 9604.5 | 4836.4 | 3490 | 8 ~100 | 13.8 | 25.5 | 63932.5 |

| MQGg 2442 | 2400 | 4200 | JR138-8 | 320 | 10204.5 | 4836.4 | 3490 | 8 ~110 | 16 | 30 | 67370 |

| MQGg 2721 | 2700 | 2100 | JR138-8 | 245 | 8300 | 4786.4 | 3495 | 7.2 ~84 | 10.7 | 23 | 66743 |

| MQGg 2727 | 2700 | 2700 | JR137-6 | 280 | 8901 | 4786.4 | 3490 | 7 ~110 | 13.8 | 29 | 71030 |

| MQGg 2730 | 2700 | 3000 | JR1410-8 | 320 | 9610 | 5000 | 3495 | 8 ~115 | 15.3 | 32 | 83909.2 |

| MQGg 2732 | 2700 | 3200 | JR1410-8 | 320 | 10724 | 5000 | 3620 | 8 ~120 | 15.7 | 32 | 88073 |

| MQGg 2736 | 2700 | 3600 | JR158-8 | 380 | 10409 | 5150 | 3620 | 12~145 | 17.7 | 37 | 95300 |

| MQGg 2740 | 2700 | 4000 | JR158-8 | 380 | 10609 | 5150 | 3620 | 12.5 ~152 | 19 | 42 | 98454 |

| MQGg 2745 | 2700 | 4500 | JR1510-8 | 450 | 11534 | 5200 | 3670 | 13~160 | 22 | 40 | 100016 |

| MQGg 2747 | 2700 | 4700 | JR1510-8 | 475 | 11779 | 5571 | 4175 | 13~170 | 23 | 45 | 101645 |

| MQGg 2760 | 2700 | 6000 | JR1512-8 | 630 | 13299 | 5540.6 | 5140 | 15~200 | 30 | 60 | 119546 |

| MQGg 2836 | 2800 | 3600 | JR1510-8 | 400 | 10964 | 5350 | 3670 | 13~160 | 19.7 | 41 | 106350 |

| MQGg 3231 | 3200 | 3100 | TDMK630-36 | 630 | 12750 | 6750 | 5150 | 14~180 | 22.5 | 45 | 115430 |

| MQGg 3245 | 3200 | 4500 | TDMK800-36 | 800 | 13896 | 7200 | 5152.5 | 95~110 | 32.8 | 65 | 147588 |

| MQGg 3645 | 3600 | 4500 | TDMK1250-40 | 1250 | 18280 | 7700 | 5496 | 115~170 | 41.5 | 76 | 195727 |

Guestbook

Please leave your message here! We will send detail technical info and quotation to you!

Related Products

Raymond Mill | Cylinder Energy-Saving Overflow Ball Mill | Autogenous Mill |

Mineral Processing

EPC and Equipment

Tel: 0086 13025991453

E-mail: marketing@ytxinhai.com

Home

About us

EPC

Products

Solutions

Cases

News

Contact Us

3D Exhibition Room

sitemap

© 2014 Shandong Xinhai Mining Technology & Equipment Inc.