- Home

- About us

- Mineral Processing EPC

- Products

-

- Crushing

- Screening

- Grinding

- Classifying

- Agitation Equipment

- Flotation

- Gravity Separation Equipment

- Magnetic Equipment

- Thickening

- Dewatering Machine

- Gold Extraction Equipment

- Feeding

- Transmission Equipment

- Iron Removal Equipment

- Automatic Control Equipment

- Wear – Resistant Rubber Products

- Valves

- Hydrocyclone

- Pumps

-

- Solutions

-

- Gold CIP Production Line

- Gold CIL Processing Line

- Gold Flotation Production Line

- Cu-Pb-Zn Dressing Process

- Gold Heap Leaching Process

- Molybdenum Dressing Production Line

- Quartz Sand Dressing Production Line

- Hematite Separation Process

- Phosphorite Flotation Equipment Production Line

- Manganese Ore Magnetic Separation Production Line

- Magnetite Separation Production Line

- Scheelite Flotation Production Line

- Fluorite Flotation Process

- Silver Flotation Process

- Barite Mineral Processing

- Antimony Mineral Processing

- Wolframite Mineral Processing

- Chrome Ore Mining Process

- Iron Ore Mining Process

- Tin Ore Mining Process

- Nickel Ore Mining Process

- Graphite Ore Beneficiation Process

- Tailings Re-Processing Line

- Titanium Mining Process

- Dolomite Mining Process

- Kaolin Mining Process

- Pyrite Mineral Process

- Zircon Ore Mining Process

- Magnesite Flotation Process

- More >>>

-

- Cases

- News

- Contact Us

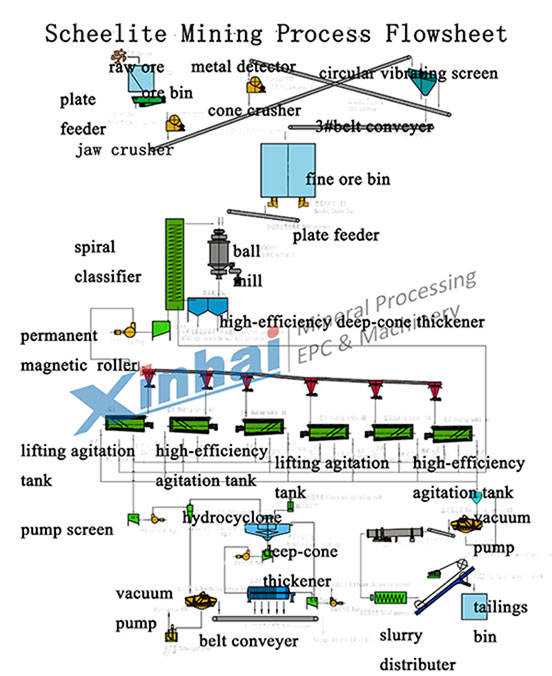

Scheelite Flotation Production Line

【Process Introduction】

Scheelite dressing can use gravity, magnetic and flotation separation. The types and properties of the ore decide the separation methods and processes. Basing on good floatability of scheelite, the flotation is selected.

【Application】

Scheelite flotation product line is suitable for the scheelite containing multi metals with complex structure

Check Process Flow >>

[Process Introduction]

Separation of scheelite and calcspar & fluorite

Concentration pulp with high temperature is common method. First, the pulp is concentrated to 60%-70%; the next, sodium silicate is added into pulp; then, the pulp is heated to 80℃ and stirred for 30-60min; the last, it is diluted with water. The floatation of scheelite is under the room temperature, and the product in tank is calcspar & fluorite.

The separation of scheelite and barite

It is difficult to separate scheelite and barite by sodium silicate because of the closed inhibitory action for scheelite and barite. We choose alkyl sulfate as collector to repeatly select barite under the 1.5-3PH, and the product in tank is scheelite.

The separation of scheelite and sulfide

Xanthate is used to capture sulfide minerals in scheelite floatation. We add a little oxide and sodium sulfide to inhibit sulfide without floatation.

The separation of scheelite and Quartz silicate

Oleic acid as collector and sodium silicate as inhibitors, which could inhibit the quartz and silicate gangue and float scheelite

[Case ]

It interfered the scheelite floatation index for complex composition, fine particle size of distribution and containing fluorite and other mineral rich of Ca & Fe. The dressing plant takes the processing: one roughing, four cleaning and two scavenging, but the final grade of scheelite was not high only 55%. So they authorize Xinhai to do technical reconstruction. Xinhai decided to use centrifugal flotation process after analyzing the properties of ore, the detailed index comparison as follow

| Comparison of Reconstruction | Process | Concentrate Grade/% | Recovery Rate/% |

| Before Reconstruction | Flotation | 57.85 | 88.18 |

| After Reconstruction | Centrifugal Flotation | 62.59 | 93.26 |

After the reconstruction, it obviously strengthens the recovery of fine particle and reduces the effect of mud on the separation process. The recovery index becomes better realizing the comprehensive recycling of resources.

[Related Products]

[ Process Flow ]

Guestbook

Please leave your message here! We will send detail technical info and quotation to you!

Mineral Processing

EPC and Equipment

Tel: 0086 13025991453

E-mail: marketing@ytxinhai.com

Home

About us

EPC

Products

Solutions

Cases

News

Contact Us

3D Exhibition Room

sitemap

© 2014 Shandong Xinhai Mining Technology & Equipment Inc.