- Home

- About us

- Mineral Processing EPC

- Products

-

- Crushing

- Screening

- Grinding

- Classifying

- Agitation Equipment

- Flotation

- Gravity Separation Equipment

- Magnetic Equipment

- Thickening

- Dewatering Machine

- Gold Extraction Equipment

- Feeding

- Transmission Equipment

- Iron Removal Equipment

- Automatic Control Equipment

- Wear – Resistant Rubber Products

- Valves

- Hydrocyclone

- Pumps

-

- Solutions

-

- Gold CIP Production Line

- Gold CIL Processing Line

- Gold Flotation Production Line

- Cu-Pb-Zn Dressing Process

- Gold Heap Leaching Process

- Molybdenum Dressing Production Line

- Quartz Sand Dressing Production Line

- Hematite Separation Process

- Phosphorite Flotation Equipment Production Line

- Manganese Ore Magnetic Separation Production Line

- Magnetite Separation Production Line

- Scheelite Flotation Production Line

- Fluorite Flotation Process

- Silver Flotation Process

- Barite Mineral Processing

- Antimony Mineral Processing

- Wolframite Mineral Processing

- Chrome Ore Mining Process

- Iron Ore Mining Process

- Tin Ore Mining Process

- Nickel Ore Mining Process

- Graphite Ore Beneficiation Process

- Tailings Re-Processing Line

- Titanium Mining Process

- Dolomite Mining Process

- Kaolin Mining Process

- Pyrite Mineral Process

- Zircon Ore Mining Process

- Magnesite Flotation Process

- More >>>

-

- Cases

- News

- Contact Us

ZSW Vibrating Feeder

- Product Introduction

- A mechanical vibrating feeding equipment with rough screening function

- Capacity

- 96~560t/h

- Product Improvement

- 1、Baseboard of feeding tank adopts “Blind plate + screen” to pre-screen the small block materials

- 2、Double eccentric shaft vibrator

Advantages

Stable operation, reliable work, long service life, continuous and feeding for crushing, rough screening, and it is widely used in mineral processing, building materials, silicate and chemical industry etc.

Work Principle

The vibration exciter is composed of two eccentric shafts with particular position. The large linear vibration force produced by motor and the rotation of two eccentric shafts vibrates the machine. The materials are sliding and thrown so that it could move on. When the materials pass the screen bars, the small ore falls through the clearance of screen bars.

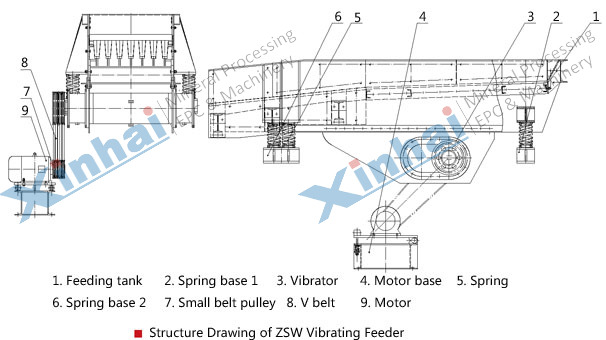

Product Structure

ZSW series vibrating feeder is composed of vibrating frame, spring, vibrator, motor vibration frame and motor etc.

Product Application

Mainly applied in feeding for conveyor, bucket type lifting machine, crusher, ball mill, and also used in automatic control system to realize the automation of production process.

Feeding for coarse crusher, screening fine materials to increase crusher capacity

For transporting ferrous or non-ferrous metal ores, building materials but sticky wet material

Widely used in metallurgy, mining, mineral processing, building materials, chemical industry, and other industries

Technical Parameters

| Model | Tank Dimensions (mm) | Max. Feed Size (mm) | Feed Capacity (t/h) | Rotating Speed of Eccentric Shaft (r/min) | Motor Power (kW) |

Weight (kg) |

| ZSW380X95 | 3800X950 | 500 | 96~160 | 800 | 11 | 4082 |

| ZSW420X110 | 4200X1100 | 500 | 110~180 | 800 | 15 | 4149 |

| ZSW490X110 | 4900X1100 | 500 | 115~192 | 800 | 15 | 4263 |

| ZSW590X110 | 5900X1100 | 630 | 350~500 | 800 | 22 | 6130 |

| ZSW600X130 | 6000X1300 | 750 | 400~560 | 800 | 7800 |

Guestbook

Please leave your message here! We will send detail technical info and quotation to you!

Related Products

Disc Feeder | Belt Feeder | Electromagnetic Vibrating Feeder |

Mineral Processing

EPC and Equipment

Tel: 0086 13025991453

E-mail: marketing@ytxinhai.com

Home

About us

EPC

Products

Solutions

Cases

News

Contact Us

3D Exhibition Room

sitemap

© 2014 Shandong Xinhai Mining Technology & Equipment Inc.