- Home

- About us

- Mineral Processing EPC

- Products

-

- Crushing

- Screening

- Grinding

- Classifying

- Agitation Equipment

- Flotation

- Gravity Separation Equipment

- Magnetic Equipment

- Thickening

- Dewatering Machine

- Gold Extraction Equipment

- Feeding

- Transmission Equipment

- Iron Removal Equipment

- Automatic Control Equipment

- Wear – Resistant Rubber Products

- Valves

- Hydrocyclone

- Pumps

-

- Solutions

-

- Gold CIP Production Line

- Gold CIL Processing Line

- Gold Flotation Production Line

- Cu-Pb-Zn Dressing Process

- Gold Heap Leaching Process

- Molybdenum Dressing Production Line

- Quartz Sand Dressing Production Line

- Hematite Separation Process

- Phosphorite Flotation Equipment Production Line

- Manganese Ore Magnetic Separation Production Line

- Magnetite Separation Production Line

- Scheelite Flotation Production Line

- Fluorite Flotation Process

- Silver Flotation Process

- Barite Mineral Processing

- Antimony Mineral Processing

- Wolframite Mineral Processing

- Chrome Ore Mining Process

- Iron Ore Mining Process

- Tin Ore Mining Process

- Nickel Ore Mining Process

- Graphite Ore Beneficiation Process

- Tailings Re-Processing Line

- Titanium Mining Process

- Dolomite Mining Process

- Kaolin Mining Process

- Pyrite Mineral Process

- Zircon Ore Mining Process

- Magnesite Flotation Process

- More >>>

-

- Cases

- News

- Contact Us

JJF Flotation, Wemco Flotation

- Introduction

- A self-air suction mechanical stirring floatation cell without slurry suction (Referring to the design of USA wemco flotation machine)

- Effective Volume

- 4~20m3

- Product Improvement

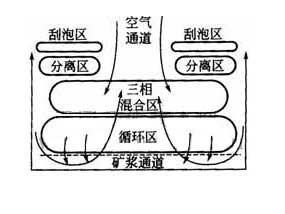

- Shallow groove, the stator lower than the impeller, large slurry circulation volume, low energy consumption; the stator is a cylinder with an elliptical hole which is conducive to the dispersion and mixing of pulp and air. Umbrella shaped dispersion cover with hole keeps the pulp surface stable.

Advantages

Large pulp circulation volume up to 2.5 times, is conducive to mineralization of pulp, reagents and air

Large air suction volume, good dispersion effect

Reasonable circulation of mineral slurry and the solid particles suspend well, no sediment in tank, and no need to feed mine when it stopped.

Wide range of particle size and high recovery rate of ore selection

Mechanical agitation; self-air suction but not slurry; ladder is necessary during processing (drop height: 300-400 mm)

It can be combined with model SF as a flotation cells set: model SF as the suction cell and model JJF as the direct flow cell.

Work Principle

When the flotation machine works, the motor drives the impeller to revolve, so the centrifugal effect and negative pressure are produced. On one hand, ample air is absorbed and mixed with mineral slurry, on the other hand, the mixed mineral slurry is mingled with additive, meanwhile, the foams are thinning, the mineral is bounded with foams, and floats up to the surface of mineral slurry and the mineralized foam is formed. The liquid surface can be adjusted with the height of adjustment flashboard, so that the useful foams are scraped with squeegee.

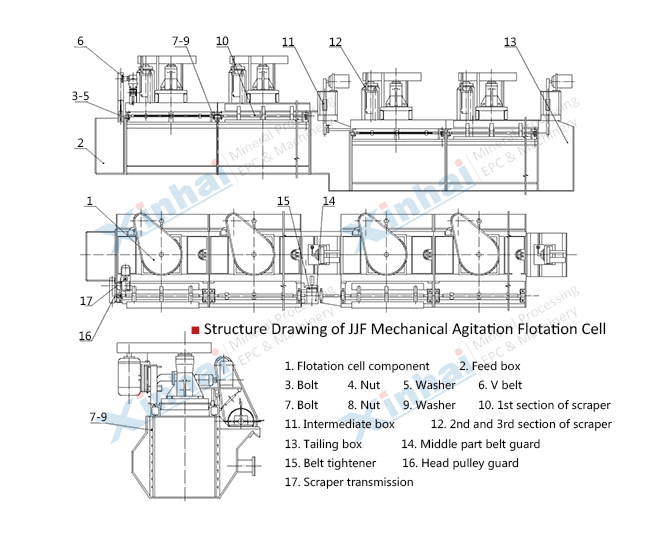

Product Structure

JJF type flotation machine is mainly composed of tank body, impeller, stator, dispersing cover, false low, draft tube, vertical tube, adjusting ring.

Shallow tank, small diameter, low rotary speed, and low power consumption.

Large clearance between impeller and stator, the stator is a cylinder with elliptic hole, and it is good for mixing and dispersing the gas and pulp.

The height of stator is lower than impeller, pulp circulation volume is large, and it can be reached at 2.5 times of others.

The umbrella-type dispersion cover with holes of the stator can separate the eddy current and bubbles that produced by impeller, so as to keep the pulp surface stable.

Flotation cell is widely used for separating non-ferrous metal, black metal, noble metal, non-metal mineral, raw body and materials of chemical industry, which are subject to roughing and scavenging of large and middle scale floatation plants.

Technical Parameters

| Model | Effective Volume (m3) |

Capacity (m3/min) |

Impeller Diameter (mm) |

Impeller Revolution (r/min) |

Motor Power for Agitation (kW) | Motor Power for Scraper (kW) | Single Tank Weight (kg) |

| JJF-4 | 4 | 2.0~4 | 410 | 305 | 11 | 1.5 | 2303 |

| JJF-5 | 5 | 2.0~6 | 410 | 305 | 11 | 1.5 | 2416 |

| JJF-8 | 8 | 4.0~12 | 540 | 233 | 22 | 2.2 | 4507 |

| JJF-10 | 10 | 5.0~10 | 540 | 233 | 22 | 1.5 | 4820 |

| JJF-16 | 16 | 5.0~16 | 700 | 180 | 37 | 1.5 | 7657 |

| JJF-20 | 20 | 5.0~20 | 770 | 180 | 45 | 1.5 | 8505 |

Related Articles

Guestbook

Please leave your message here! We will send detail technical info and quotation to you!

Related Products

XJB Bar Flotation Cell | XCF air inflation flotation cell | KYF Air Inflation Flotation Cell |

Mineral Processing

EPC and Equipment

Tel: 0086 13025991453

E-mail: marketing@ytxinhai.com

Home

About us

EPC

Products

Solutions

Cases

News

Contact Us

3D Exhibition Room

sitemap

© 2014 Shandong Xinhai Mining Technology & Equipment Inc.