- Home

- About us

- Mineral Processing EPC

- Products

-

- Crushing

- Screening

- Grinding

- Classifying

- Agitation Equipment

- Flotation

- Gravity Separation Equipment

- Magnetic Equipment

- Thickening

- Dewatering Machine

- Gold Extraction Equipment

- Feeding

- Transmission Equipment

- Iron Removal Equipment

- Automatic Control Equipment

- Wear – Resistant Rubber Products

- Valves

- Hydrocyclone

- Pumps

-

- Solutions

-

- Gold CIP Production Line

- Gold CIL Processing Line

- Gold Flotation Production Line

- Cu-Pb-Zn Dressing Process

- Gold Heap Leaching Process

- Molybdenum Dressing Production Line

- Quartz Sand Dressing Production Line

- Hematite Separation Process

- Phosphorite Flotation Equipment Production Line

- Manganese Ore Magnetic Separation Production Line

- Magnetite Separation Production Line

- Scheelite Flotation Production Line

- Fluorite Flotation Process

- Silver Flotation Process

- Barite Mineral Processing

- Antimony Mineral Processing

- Wolframite Mineral Processing

- Chrome Ore Mining Process

- Iron Ore Mining Process

- Tin Ore Mining Process

- Nickel Ore Mining Process

- Graphite Ore Beneficiation Process

- Tailings Re-Processing Line

- Titanium Mining Process

- Dolomite Mining Process

- Kaolin Mining Process

- Pyrite Mineral Process

- Zircon Ore Mining Process

- Magnesite Flotation Process

- More >>>

-

- Cases

- News

- Contact Us

Hydraulic Cone Crusher

- Product Introduction

- Hydraulic cone crusher is a kind of crushing equipment

- Production Capacity

- 5~750t/h

- Product Improvement

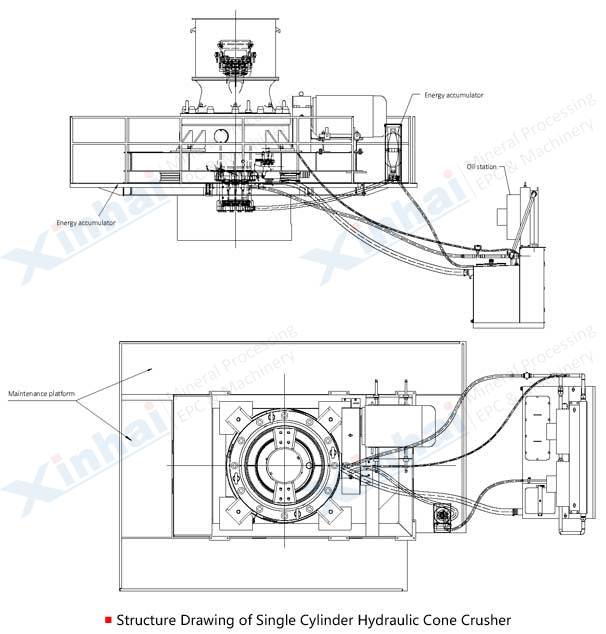

- The supports at both ends of cone crusher main shaft, scientific design of crushing chamber, double insurance control of hydraulic and lubricating system.

Advantages

The hydraulic cone crusher owns support at both ends of main shaft which can bear larger crushing force improving the crushing efficiency. Processing capacity is increased 35% ~ 60% than old type spring cone crusher.

Scientific design of crushing chamber and laminated crushing principle improve the cube proportion in end product and reduce the needle flake type stone. The particle size becomes more uniform.

Double safety control of hydraulic and lubricating system protects this cone crusher machine from overload, and lubricates bearings better.

Work Principle

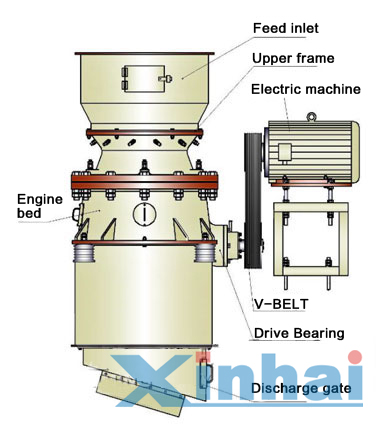

Hydraulic cone crusher consists of frame, transmission, hollow eccentric shaft, bowl-shaped bearing, crushing cone, springs and hydraulic pressure station for adjusting discharge opening. The working principle of hydraulic cone crusher is like, the motor drives eccentric shaft shell to rotate through a horizontal axle and a pair of bevel gear during operation, . The axle of crushing cone swings with the force of eccentric shaft shell so that the surface of the crushing wall is close to the roll mortar wall from time to time. In this way, the ores and rocks will be pressed and crooked and crushed.

Product Structure

Hydraulic cone crushers are widely applied in metallurgical, construction, road building, chemical and phosphatic industry. It is suitable for hard and mid-hard rocks and ores, such as iron ores, copper ores, limestone, quartz, granite, grit stone, etc. Xinhai as an excellent cone crusher manufacturer provides the most suitable price for you.

Technical Parameters

| Model | Cavity | Inlet Dimension (mm) | Max. Feed Size (mm) | Min. Outlet Dimension (mm) | Max. Feed Dimension (mm) | Power (kW) |

Weight (t) |

||||

| Stroke | Stroke | Stroke | Stroke | Stroke | Stroke | ||||||

| PYY100 | 16 | 22 | 16 | 22 | 90 | 6 | |||||

| A | 150 | 120 | 12 | 15 | 39 | 37 | |||||

| B | 130 | 105 | 10 | 11 | 33 | 31 | |||||

| C | 100 | 85 | 7 | 9 | 33 | 30 | |||||

| D | 40 | 32 | 5 | 6 | 31 | 29 | |||||

| PYY200 | 18 | 25 | 18 | 25 | 160 | 10.6 | |||||

| A | 220 | 180 | 18 | 22 | 35 | 30 | |||||

| B | 150 | 120 | 15 | 19 | 35 | 30 | |||||

| C | 80 | 60 | 9 | 12 | 35 | 30 | |||||

| D | 40 | 32 | 6 | 8 | 35 | 30 | |||||

| PYY300 | 25 | 32 | 25 | 32 | 250 | 18.5 | |||||

| A | 230 | 190 | 20 | 25 | 45 | 40 | |||||

| B | 150 | 125 | 17 | 20 | 45 | 40 | |||||

| C | 80 | 60 | 10 | 13 | 40 | 35 | |||||

| D | 40 | 32 | 6 | 8 | 40 | 35 | |||||

| PYY500 | 25 | 32 | 40 | 25 | 32 | 40 | 315 | 22.5 | |||

| A | 230 | 180 | 22 | 26 | 30 | 50 | 45 | 40 | |||

| B | 150 | 125 | 19 | 22 | 26 | 48 | 43 | 38 | |||

| C | 100 | 80 | 12 | 14 | 16 | 40 | 35 | 30 | |||

| D | 50 | 40 | 8 | 10 | 12 | 30 | 25 | 20 | |||

Related Articles

Guestbook

Please leave your message here! We will send detail technical info and quotation to you!

Related Products

Mobile Crushing and Screening Equipment | Hydraulic Cone Crusher | Spring Cone Crusher |

Mineral Processing

EPC and Equipment

Tel: 0086 13025991453

E-mail: marketing@ytxinhai.com

Home

About us

EPC

Products

Solutions

Cases

News

Contact Us

3D Exhibition Room

sitemap

© 2014 Shandong Xinhai Mining Technology & Equipment Inc.