- Home

- About us

- Mineral Processing EPC

- Products

-

- Crushing

- Screening

- Grinding

- Classifying

- Agitation Equipment

- Flotation

- Gravity Separation Equipment

- Magnetic Equipment

- Thickening

- Dewatering Machine

- Gold Extraction Equipment

- Feeding

- Transmission Equipment

- Iron Removal Equipment

- Automatic Control Equipment

- Wear – Resistant Rubber Products

- Valves

- Hydrocyclone

- Pumps

-

- Solutions

-

- Gold CIP Production Line

- Gold CIL Processing Line

- Gold Flotation Production Line

- Cu-Pb-Zn Dressing Process

- Gold Heap Leaching Process

- Molybdenum Dressing Production Line

- Quartz Sand Dressing Production Line

- Hematite Separation Process

- Phosphorite Flotation Equipment Production Line

- Manganese Ore Magnetic Separation Production Line

- Magnetite Separation Production Line

- Scheelite Flotation Production Line

- Fluorite Flotation Process

- Silver Flotation Process

- Barite Mineral Processing

- Antimony Mineral Processing

- Wolframite Mineral Processing

- Chrome Ore Mining Process

- Iron Ore Mining Process

- Tin Ore Mining Process

- Nickel Ore Mining Process

- Graphite Ore Beneficiation Process

- Tailings Re-Processing Line

- Titanium Mining Process

- Dolomite Mining Process

- Kaolin Mining Process

- Pyrite Mineral Process

- Zircon Ore Mining Process

- Magnesite Flotation Process

- More >>>

-

- Cases

- News

- Contact Us

Home > Products > Gold Extraction Equipment >Washing Thickener

Washing Thickener

- Product Introduction

- Washing thickener for solid-liquid separation of gold leaching liquid

- Capacity

- 10-250t/h

- Product Features

- 1, Countercurrent washing, large capacity and high washing efficiency

- 2, Small area taken

- 3, Stable production and convenient operation

- 2, Small area taken

Advantages

The continuous ore discharge method can reduce the multiple cycle of liquid gold, while extending the time of pulp staying in the washing thickener to improve the leaching rate;

Countercurrent washing, large capacity and high washing efficiency

Small area taken, reasonable structure and low cost of operation and maintenance

Work Principle

Ore pulps enter into tank and then free settle in rake zone where ore pulps are compressed by scraper and moved by rake toward the discharge opening located in tank center through which ore pulps are discharged to next tank. Via distributing box, clear water enters the lowest layer to scrub minerals. After that, overflow of the lowest layer comes back to distributing box to scrub minerals of upper layer. Overflow of first layer is discharged through overflow weir; minerals----which are scrubbed for three times----are discharged from bottom end.

It is mainly used to countercurrent scrubbing of gold cyaniding process. Three layers washing thickener is also applicable to scrubbing and dehydration in wet metallurgy, light industry and chemical industry.

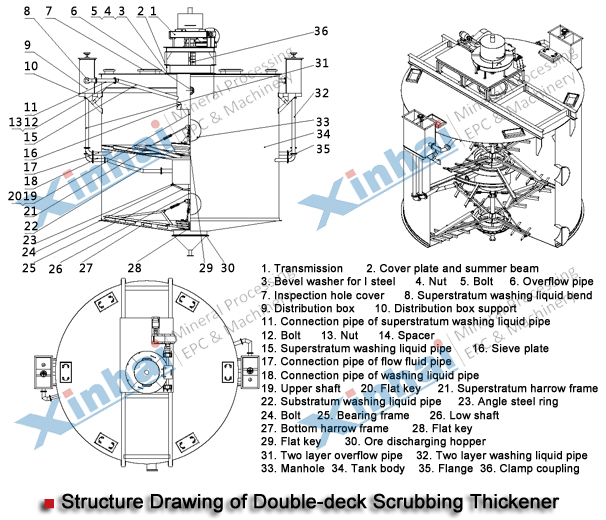

Product Structure

Technical Parameters

Spec. |

Diameter |

Depth of Center Tank (m) |

Subsidence Area (m2) |

Revolution of Harrow Frame (r/min) |

Capacity |

Motor Model |

Motor |

Weight |

Remarks |

2NZS6 |

6 |

5.34 |

56.5 |

0.25 |

≤ 50 |

Y112M-6 |

2.2 |

13360 |

Excluding the pond weight |

2NZS7 |

7 |

5.41 |

77 |

≤ 56 |

14200 |

||||

2NZS8 |

8 |

6.08 |

100.7 |

0.28 |

≤ 68 |

Y132M1-6 |

4 |

50449 |

Including the pond weight |

2NZS9 |

9 |

5.91 |

127.3 |

≤ 88 |

54628 |

||||

2NZS12 |

12 |

6.87 |

226 |

0.2 |

≤ 160 |

Y132M2-6 |

5.5 |

40400 |

Excluding the pond weight |

2NZS15 |

15 |

6.95 |

353.3 |

0.15 |

≤ 250 |

51470 |

Guestbook

Please leave your message here! We will send detail technical info and quotation to you!

Related Products

Zinc Powder Displacement Device | Washing Thickener | Desorption Electrolysis System |

Mineral Processing

EPC and Equipment

Tel: 0086 13025991453

E-mail: marketing@ytxinhai.com

Home

About us

EPC

Products

Solutions

Cases

News

Contact Us

3D Exhibition Room

sitemap

© 2014 Shandong Xinhai Mining Technology & Equipment Inc.