- Home

- About us

- Mineral Processing EPC

- Products

-

- Crushing

- Screening

- Grinding

- Classifying

- Agitation Equipment

- Flotation

- Gravity Separation Equipment

- Magnetic Equipment

- Thickening

- Dewatering Machine

- Gold Extraction Equipment

- Feeding

- Transmission Equipment

- Iron Removal Equipment

- Automatic Control Equipment

- Wear – Resistant Rubber Products

- Valves

- Hydrocyclone

- Pumps

-

- Solutions

-

- Gold CIP Production Line

- Gold CIL Processing Line

- Gold Flotation Production Line

- Cu-Pb-Zn Dressing Process

- Gold Heap Leaching Process

- Molybdenum Dressing Production Line

- Quartz Sand Dressing Production Line

- Hematite Separation Process

- Phosphorite Flotation Equipment Production Line

- Manganese Ore Magnetic Separation Production Line

- Magnetite Separation Production Line

- Scheelite Flotation Production Line

- Fluorite Flotation Process

- Silver Flotation Process

- Barite Mineral Processing

- Antimony Mineral Processing

- Wolframite Mineral Processing

- Chrome Ore Mining Process

- Iron Ore Mining Process

- Tin Ore Mining Process

- Nickel Ore Mining Process

- Graphite Ore Beneficiation Process

- Tailings Re-Processing Line

- Titanium Mining Process

- Dolomite Mining Process

- Kaolin Mining Process

- Pyrite Mineral Process

- Zircon Ore Mining Process

- Magnesite Flotation Process

- More >>>

-

- Cases

- News

- Contact Us

Home > Products > Gold Extraction Equipment >Leaching Agitation Tank

Leaching Agitation Tank

- Product Introduction

- Leaching agitaion tank is a leaching equipment for cyanide leaching by referring the USA technical design

- Effective Volume

- 6-395m3

- Product Improvement

- Leaching agitation tank for gold extraction with double impeller, uniform mixing, low energy consumption; the impeller coated by rubber, long service life; multi points to give gas, uniform inflation

Advantages

Entering leaching tank via hollow shaft, air is agitated and dispersed by rotation of impellers.

The two new type impellers with large diameter, low speed and low power consumption, which can reduce the wear of carbon

The moderate stirring intensity, pulp concentration and fineness distributes consistently can improve the adsorption rate and import rate.

Work Principle

With dual impellers rotating and agitating, ore pulps move downward and then diffuse along damping plate. Air is fed in tank from the lower end of shaft, and blended with ore pulps to form uniform suspending mixed liquid.

In the gold cyaniding process, leaching agitation tank is applied to leach and carbon-absorb ore pulps whose fineness is -200 meshes and whose density is less than 45%. Under similar circumstance, it is also applied to agitation and leaching in metallurgy, chemical and light industry.

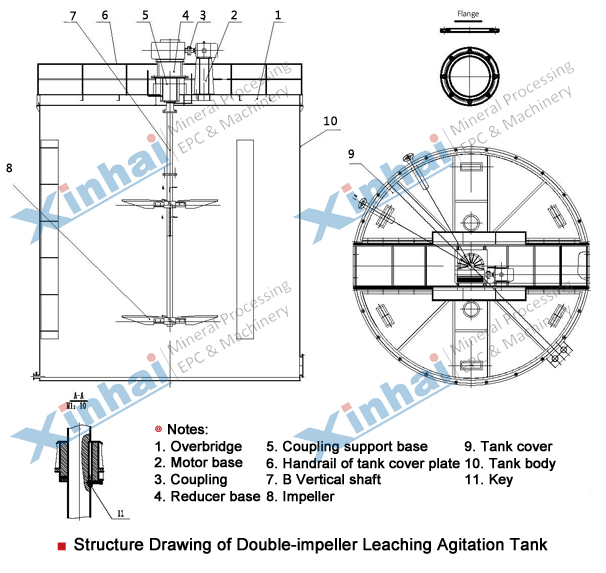

Product Structure

Technical Parameters

| Model | Tank Spec. (DX H) (mm) |

Effective Volume (m3) |

Rotating Speed of Impeller (r/min) | Diameter of Impeller (mm) | Motor Model |

Motor Power (kW) |

Reducer Model | Tank Weight (kg) |

Total Weight (kg) |

| SJ2.0X2.5 | 2000X2500 | 7.07 | 52 | 909 | Y100L1-4 | 2.2 | XLD2.2-4-29 | 1609 | 2144 |

| SJ2.5X2.5 | 2500X2500 | 10.8 | 43 | 935 | Y112M-4 | 4 | XLD4-5-35 | 2159 | 2729 |

| SJ2.5X3.15 | 2500X3150 | 13.92 | 52 | 935 | Y100L1-4 | 2.2 | XLD2.2-4-29 | 2398 | 3095 |

| SJ3.0X3.0 | 3000X3000 | 19 | 43 | 1130 | Y112M-4 | 4 | XLD4-5-35 | 3480 | 4583 |

| SJ3X3.15 | 3000X3150 | 20 | 3480 | 4160.6 | |||||

| SJ3X3.5 | 3000X3500 | 22.97 | 3211 | 4334.6 | |||||

| SJ3.15X3.55 | 3150X3550 | 25.73 | 1260 | 3433.5 | 4322.8 | ||||

| SJ3.5X3.5 | 3500X3500 | 31.3 | 52 | 1310 | Y132S-4 | 5.5 | XLD5.5-5-29 | 3480 | 5025 |

| SJ3.5X4 | 3500X4000 | 35.6 | 4230 | 5429 | |||||

| SJ3.55X4.0 | 3550X4000 | 36.8 | 43 | 4 | XLD4-5-35 | 4260 | 5025 | ||

| SJ3.7X4.2 | 3700X4200 | 42 | 42 | Y112M-4 | XLD4-5-43 | 5266 | 6153 | ||

| SJ4.0X4.5 | 4000 X4500 | 52.78 | 35 | 1750 | Y132M-4 | 7.5 | XLD7.5-7-43 | 6397 | 7569 |

| SJ4.0X6 | 4000 X6000 | 71 | 33 | 1750 | Y160M-4 | 11 | GRF137-Y11-4P-44.65-M4 | 7681 | 9200 |

| SJ4.5X5.0 | 4500 X5000 | 74.75 | 35 | 1750 | Y132M-4 | 7.5 | XLD7.5-7-43 | 8614 | 10864 |

| SJ5.0X5.6 | 5000X5600 | 104.5 | 31 | 2046 | Y160M-4 | 11 | XLD11-8-47 | 8740 | 14291 |

| SJ5.5X6.0 | 5500X6000 | 135.42 | 2100 | 12467 | 18745 | ||||

| SJ6.5X7.0 | 6500X7000 | 215 | 21 | 2400 | Y180L-4 | 22 | GRF147-Y22-4P-70.87 | 17890 | 25978 |

| SJ7.0X7.5 | 7000 X7500 | 269 | 2400 | Y200L2-6 | 22 | XLD22-10-47 | 20505 | 29030 | |

| SJ7.5X8.0 | 7500 X8000 | 331 | 23 | 2900 | Y200L2-6 | 22 | BLD7-43-22L | 22552 | 32796 |

| SJ8.0X8.5 | 8000X8500 | 402 | 18.5 | 3300 | Y250M-8 | 30 | TPS315-3F | 30559.5 | 42467.3 |

| SJ8.5X9.0 | 8500X9000 | 480 | 18.5 | 3300 | Y250M-8 | 30 | TPS315-3F | 34130 | 46623 |

Related Articles

Guestbook

Please leave your message here! We will send detail technical info and quotation to you!

Related Products

Zinc Powder Displacement Device | Washing Thickener | Desorption Electrolysis System |

Mineral Processing

EPC and Equipment

Tel: 0086 13025991453

E-mail: marketing@ytxinhai.com

Home

About us

EPC

Products

Solutions

Cases

News

Contact Us

3D Exhibition Room

sitemap

© 2014 Shandong Xinhai Mining Technology & Equipment Inc.