- Home

- About us

- Mineral Processing EPC

- Products

-

- Crushing

- Screening

- Grinding

- Classifying

- Agitation Equipment

- Flotation

- Gravity Separation Equipment

- Magnetic Equipment

- Thickening

- Dewatering Machine

- Gold Extraction Equipment

- Feeding

- Transmission Equipment

- Iron Removal Equipment

- Automatic Control Equipment

- Wear – Resistant Rubber Products

- Valves

- Hydrocyclone

- Pumps

-

- Solutions

-

- Gold CIP Production Line

- Gold CIL Processing Line

- Gold Flotation Production Line

- Cu-Pb-Zn Dressing Process

- Gold Heap Leaching Process

- Molybdenum Dressing Production Line

- Quartz Sand Dressing Production Line

- Hematite Separation Process

- Phosphorite Flotation Equipment Production Line

- Manganese Ore Magnetic Separation Production Line

- Magnetite Separation Production Line

- Scheelite Flotation Production Line

- Fluorite Flotation Process

- Silver Flotation Process

- Barite Mineral Processing

- Antimony Mineral Processing

- Wolframite Mineral Processing

- Chrome Ore Mining Process

- Iron Ore Mining Process

- Tin Ore Mining Process

- Nickel Ore Mining Process

- Graphite Ore Beneficiation Process

- Tailings Re-Processing Line

- Titanium Mining Process

- Dolomite Mining Process

- Kaolin Mining Process

- Pyrite Mineral Process

- Zircon Ore Mining Process

- Magnesite Flotation Process

- More >>>

-

- Cases

- News

- Contact Us

Home > Products > Dewatering Machine>High Frequency Dewatering Screen

High Frequency Dewatering Screen

- Product Introduction

- A multi frequency dewatering screen with large capacity and full dehydration

- Capacity

- ≤250t/h

- Product Improvement

- The efficient multi frequency dewatering screen adoptsscreen side opening holes, and the water flows out from the hole quickly accelerating the dewatering speed, in addition, it avoids the damage due to water splashed onto the motor.

Advantages

Xinhai Company has many special technical designs in dewatering screen. The main deck of the screen slopes upwards and forms a 45° sloping with the back-deck section. Two vibration motors are installed horizontally. One is installed on the top of the other one. Unbalanced gravity produces rotary effect makes the screen work stably

Double vibration motor excitation, firm and compact structure, getting rid of thedefectsof traditional eccentric vibrator such as large structure, oil leakage, large wear, large noise, inconvenient repair, etc.

Xinhai wear-resistant rubber lined on the side guard plate of Xinhai dewatering screen protects it from wearing and reduces the pollution of iron.

Xinhai mine dewatering screen uses the Xinhai embedded wear-resistant urethane mesh, its life is 3-10 times longer than the traditional metal mesh’s, and it avoids direct collision of metal frame and ore.

Vibration damper for dewatering screen is used Xinhai rubber damper column, which is more suitable for wet conditions, and is durable.

Work Principle

The product adopts double vibration motor as power supply: The two motors that rotate synchronously and reversely and centrifugal force is produced by two groups of eccentric block. This makes the screen body periodical to-and-fro moving along the direction of straight line, which is for the purpose of dehydration. The screen frame is connected by the high-intensity bolts, so the structure is stable and durable.

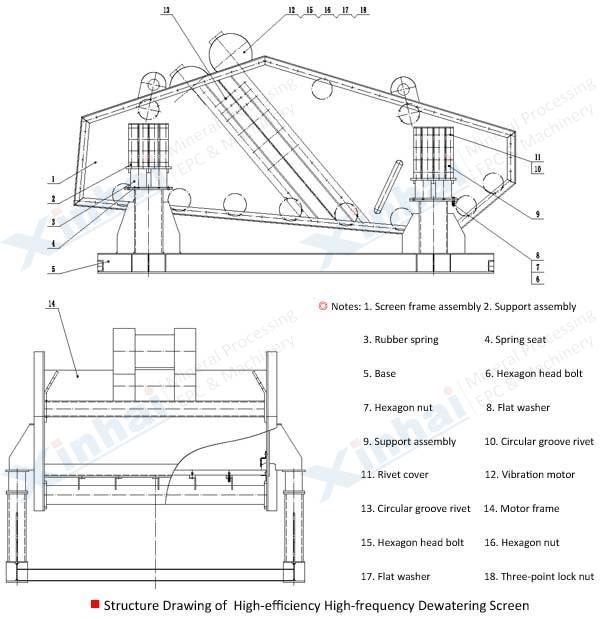

Product Structure

Product Application

Xinhai high efficiency multi frequency dewatering screen can be widely used in tailings dry stacking, fine mineral dewatering, chip removing, carbon-in-pulp separation etc.

The efficient multi frequency dewatering screen is particularly suitable for processing fine minerals. In addition, it combined with Xinhai cyclone is more efficient and can be widely used for tailings dry stacking, concentrate dewatering and so on.

Technical Parameters

| Model | Min. 30% Solid Feeding Slurry Concentration by Volume | Unit Motor Power (kW) X Quantity (set) | ||||||

| Coal Fine Theoretically -0.5+0.1(mm) Specific Gravity 1.5 | Coarse Sand Approxilly- 5(mm) 100%, -0.6(mm)50%, Specific Gravity 2.7 | Fine Sand 90% -1(mm) Specific Gravity 2.7 | 980 (r/min) | 1460 (r/min) | ||||

| 1460 (r/min) | 980 (r/min) | 1460 (r/min) | 980 (r/min) | 1460 (r/min) | 980 (r/min) | |||

| VD6 | 6~8 | 10 ~13 | 14 | 28 | 10 | 21 | 2 X2 | |

| VD9 | 9~12 | 15 ~20 | 21 | 42 | 16 | 32 | 3X2 | |

| VD12 | 15 ~19 | 24 ~30 | 33 | 67 | 25 | 50 | 2.6X2 | 4X2 |

| VD15 | 30 ~35 | 50 ~60 | 63 | 125 | 47 | 94 | 2.4X4 | 2.25X4 |

| VD18 | 35~45 | 60 ~80 | 77 | 153 | 57 | 115 | 3.7X4 | |

| VD21 | — | 85~100 | — | 225 | — | 164 | 15 | — |

| VD24 | 95~110 | 250 | 190 | |||||

Related Articles

Guestbook

Please leave your message here! We will send detail technical info and quotation to you!

Related Products

Mineral Processing

EPC and Equipment

Tel: 0086 13025991453

E-mail: marketing@ytxinhai.com

Home

About us

EPC

Products

Solutions

Cases

News

Contact Us

3D Exhibition Room

sitemap

© 2014 Shandong Xinhai Mining Technology & Equipment Inc.